Environmental impacts of plastic injection molding

In recent years, the green movement is spreading its effect more than ever, touching all aspects of life. Businesses are being challenged to implement adjustments that reduce their carbon footprint and help the environment. While plastics tend to have a negative reputation in terms of environmental impacts, yet the plastic injection molding industry could become both economically and environmentally effective, if implemented responsibly and carefully.

What is plastic injection molding?

Injection molding is one of the most essential technologies for mass-producing thermoplastic products without the need for extra finishing. Most injection molding machines nowadays are universal, meaning they can take any type of mold within certain constraints. This process’s economics are great for items with complicated geometry, providing it an edge over other procedures. Despite the high initial cost of injection molding equipment, cost per molding decreases with scale.

Micro molding is a highly specialized technique in which micro-structured steel or aluminium molds are CNC and EDM machined to micron or even sub-micron scale tolerances, and the final molded object could weigh a fraction of a gram or its tiny features. The fundamental distinction between micro molding and standard molding technologies is the size of the shot and the precision of the injection equipment. Micro-molding machines can inject fractions of a gram with great precision because they offer better resolution feed choices, resulting in equal pressure distribution inside the cavity. Micro injection molding also employs tiny molds with highly precise core, cavities and features within.

Environmental impacts of plastic injection molding

The environmental effects of plastic injection molding might vary based on the materials used, the method itself and the types of waste created.

Material

Plastic is the key material in plastic injection molding and its environmental impacts are unavoidable, ranging from the release of greenhouse gas emissions to plastic waste found in rivers and seas. Plastic manufacture requires a lot of energy and can produce pollutants including volatile organic compounds (VOCs), sulphur dioxide and nitrogen oxides. Plastics consumption in the UK creates 26 Mt CO2e per year over the whole life cycle of plastic goods, and 80% of these emissions are caused by production, both in the UK and elsewhere. Plastics, which are sourced from fossil fuels, account for 17% of emissions, with recycling and disposal accounting for just 2.3%. Plastic packaging for end products could also be challenging to be recycled. Along with shifting market needs, alterations in customer awareness and preferences are already influencing the world of injection molding.

Customers are concerned about reducing their carbon footprint, and more producers have been able to greatly expand the usage of post-consumer recycled plastics in LDPE-manufactured components. Since April 2021, virtually all LDPE goods manufactured at the UK site have been made with at least 40% recycled polymers, with no loss in quality or performance.

Metals and other materials used in injection molding can also potentially have various environmental impacts. Metal manufacturing, such as aluminium and steel, may also be energy-intensive and polluting. The utilisation of recycled resources, such as recycled plastics, can assist lessen the environmental effect of injection molding materials, however, it might not be always possible for components used for medical purposes.

Energy

The injection molding technique and technology can potentially have an influence on the environment. Injection molding machines consume a lot of energy, and this energy can contribute to air pollution. Furthermore, the process can produce a lot of heat, which might contribute to global warming. In general, the energy efficiency of the process varies depending on the melt temperature, component weight, cycle duration, machine size, and machine efficiency. The specific energy usage of 0.3 kWh/kg is particularly efficient for thin-walled components with short cycles, and 0.6 kWh/kg might be efficient for a thicker part moulded more slowly (H. Schut, 2015). However, with a particular emphasis on the environmental effect of injection molding, engineering developments imply that injection molding machinery now uses 20%-50% less energy than it did 10 years ago (H. Schut, 2015). You can check the estimated energy consumption of injection molding machines using this calculator.

The accuracy of the electric devices allows for improved repeatability, lower noise, quicker injection times and higher energy efficiency thanks to dynamic servo-motors with breathtaking acceleration capability. Electric injection molding machines only utilize energy while they are in operation, which means that the motor output is only equal to the load needs, hence they are more energy efficient than the traditional molding machines.

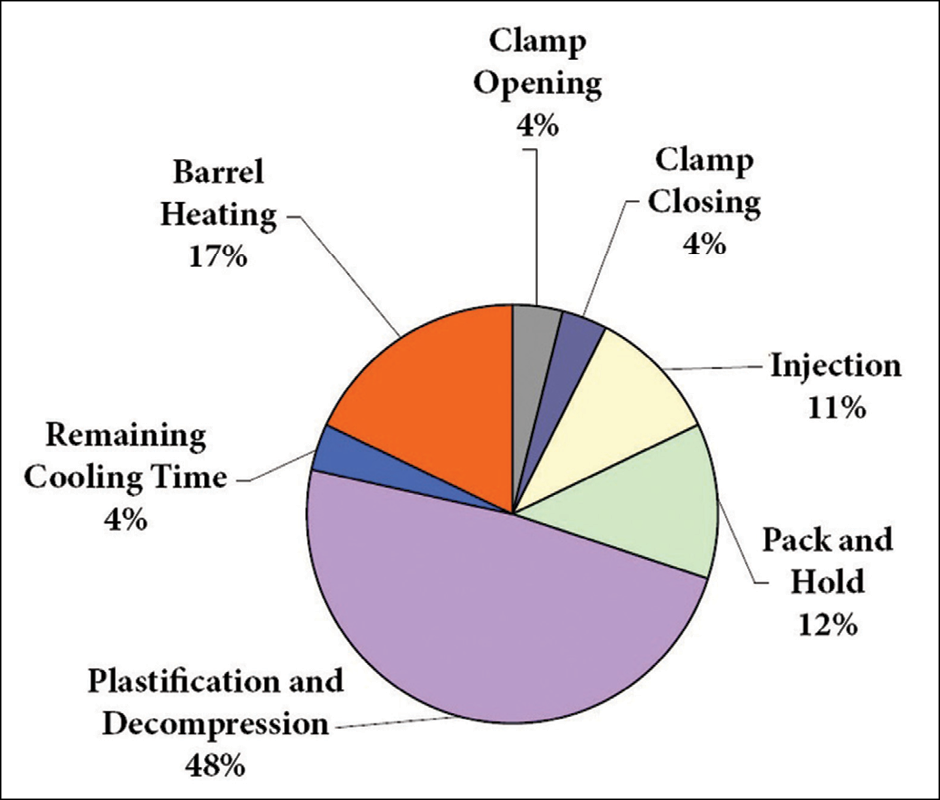

Energy ratios for an electric 100-ton injection molding machine with hydraulic injection that produces 2-mm thick walls, 83-gram ABS storage trays in 16.9-second cycles, with a specific energy use of 0.384 kWh/kg (H. Schut, 2015).

Cycle wise, the base load (energy spent when the machine is idling, such as during cooling stages) can account for 75% or more of total energy consumption in ordinary hydraulic machines, while in all-electric and hybrid machines, the base loads are typically in the 10-20% range and are primarily accounted for by barrel heating since motors only run when needed (Mobil). A high base load may suggest that the equipment is over-sized for the operation. In addition, injection molding companies could improve their environmental performance by prioritizing using renewable energy, along with frequent equipment maintenance, energy audit or applying the latest energy like Internet of thing (IoT). For instance, the new SmartPower injection molding machines of Wittmann Battenfeld are 6 times more energy efficient and 6 times less expensive to operate when compared to the early 1990’s generations. That’s why Micro Systems carefully manage energy use by only using the most-advanced, energy-efficient machinery, frequently conducting maintenance and constantly improving our human and manufacturing resources.

Current all-electric molding machines use energy ratios that are equivalent to those of previous hydraulic machines, but overall energy usage is around 50% less (Photo: Micro Systems)

Waste

Plastic injection molding generates a significant amount of plastic scrap, which can be difficult to recycle. This plastic debris might end up in landfills and take hundreds of years to disintegrate, releasing harmful compounds into the environment and polluting the air, water, and soil.

Plastic sprues are common waste materials produced during the molding process. Sprues are the bits of plastic that remain after the procedure is completed, which can be recycled locally. For example, at Micro Systems, we use a local recycling firm to re-granulate our plastic waste, including sprues as it is not just excellent for the environment, but also helps us reduce our carbon footprint by hiring local businesses to perform this service.

In addition, if manufacturers can optimize the volume, temperature, design and injection pressure of the polymer, they can ensure that the finished product is flawless without any fault, so almost-to-none of the (virgin) plastic used is wasted. When feasible, creating the ultimate mould design also means eliminating flash (extra plastic) and sprues, hence less waste is generated.

With the development of technology, together with extensive expertise and knowledge, injection molding manufacturers are getting more and more environmentally friendly, producing millions of parts a year at a lower carbon footprint. At Micro Systems, we are committed to operating with responsibility at all stages throughout our production process, such that we can fully support our customers on their journey towards sustainability in business.

Check out our 2022 CSR Report here!

References:

H. Schut, J. (no date) Plastics Engineering – March 2015, Eco-Molding: More Power for Less Energy. Available at: http://read.nxtbook.com/wiley/plasticsengineering/march2015/coverstory_ecomolding.html (Accessed: 19 May 2023).

Mobil (ed.) (no date) An Energy Saving Guide for Plastic Injection Molding Machines. Applied Market Information in association with Tangram Technology.

Micro Systems specializes in the design, manufacture and validation of ultra precision micro molds for the medical, pharmaceutical and optical markets, at the same time, the development and use of micro and nano technologies in the design and manufacture of injection molded components. We have a dedicated micro molding facility, and have ISO13485 and ISO9001 certifications. For more information, please Contact us or visit our website.