Microneedles for Drug delivery

What is Microneedles?

Microneedle provides a practical transdermal delivery method with the potential for long-term continuous medication release. It is a transdermal medication administration method with a high drug bioavailability that is painless, less intrusive, and simple to self-administer. It has been more popular as it prevents the medications from degrading in the gastrointestinal system, eliminates the discomfort and inconvenience of intravenous injection through the skin, and avoids the first-pass effects linked to the liver in the case of oral administration.

Type of Microneedles

Microneedles can vary in size and material depending on the medicine to be administered and the administration mechanism. A standard microneedle is shaped like a tapered sharp tip and measures down to micro levels, and can be made from metal, polymer, glass, silicon or ceramic. Polymer remains the most suitable for large-scale microneedle projects thanks to its ability to be manufactured repeatedly at a more affordable cost.

Solid

This kind of microneedle is made up of two parts: a transdermal patch is used to provide the medication after the microneedle array has been put to the skin to form minuscule wells that are just deep enough to reach the skin’s outermost layer. Solid microneedles are commonly used as a skin pretreatment.

Hollow

Hollow microneedles are micron-sized micro syringes with pre-loaded medication inside a hollow structure or needle cavity. The drug is delivered to the body through the pressure of the tissue fluid concentration gradient once the hollow needle tip is punctured into the skin. In addition to improving patient compliance and facilitating medication administration, hollow microneedles can significantly enhance the rate of transdermal drug delivery with greater doses and more precise delivery.

Coated

Sharp, microneedle shafts coated with a medication and affixed to a base substrate make up a coated microneedle array. Microneedles with coatings have been employed in several biological contexts.

Dissolvable

Dissolving microneedles are collections of incredibly tiny needles, usually less than 1000 μm in length, that are constructed of materials that dissolve in water. They cause the skin to become porous, and as the microneedles dissolve, the medication payload is released. Dissolving microneedles are a useful method for improving cutaneous medication administration and getting through the stratum corneum barrier.

Hydrogel-forming

Transdermal medication administration using hydrogel-forming microneedle arrays appears to be a promising substitute for conventional drug delivery techniques. Effective, regulated distribution of amoxicillin and vancomycin within similar therapeutic ranges as oral antibiotics has been made possible using hydrogel-forming microneedles.

Moulding for Microneedles

The most popular approach for creating microneedles is molding methods (Packianather et al.), in which the molds are made in a cleanroom using intricate microfabrication techniques. The creation of dissolving microneedles from biocompatible and biodegradable materials has made extensive use of micro molding, an advanced injection molding technology that has the capability to manufacture parts of micro level features, on a large scale. Micro molding is widely used for advanced medical devices, thanks to its great repeatability, accuracy, adaptability, potential cost-effectiveness, and mold reusability. However, the challenges in regulating the drug load capacity, mechanical behaviour of the polymer, and penetration depth are the constraints of this approach, making it not as popular yet as it should be.

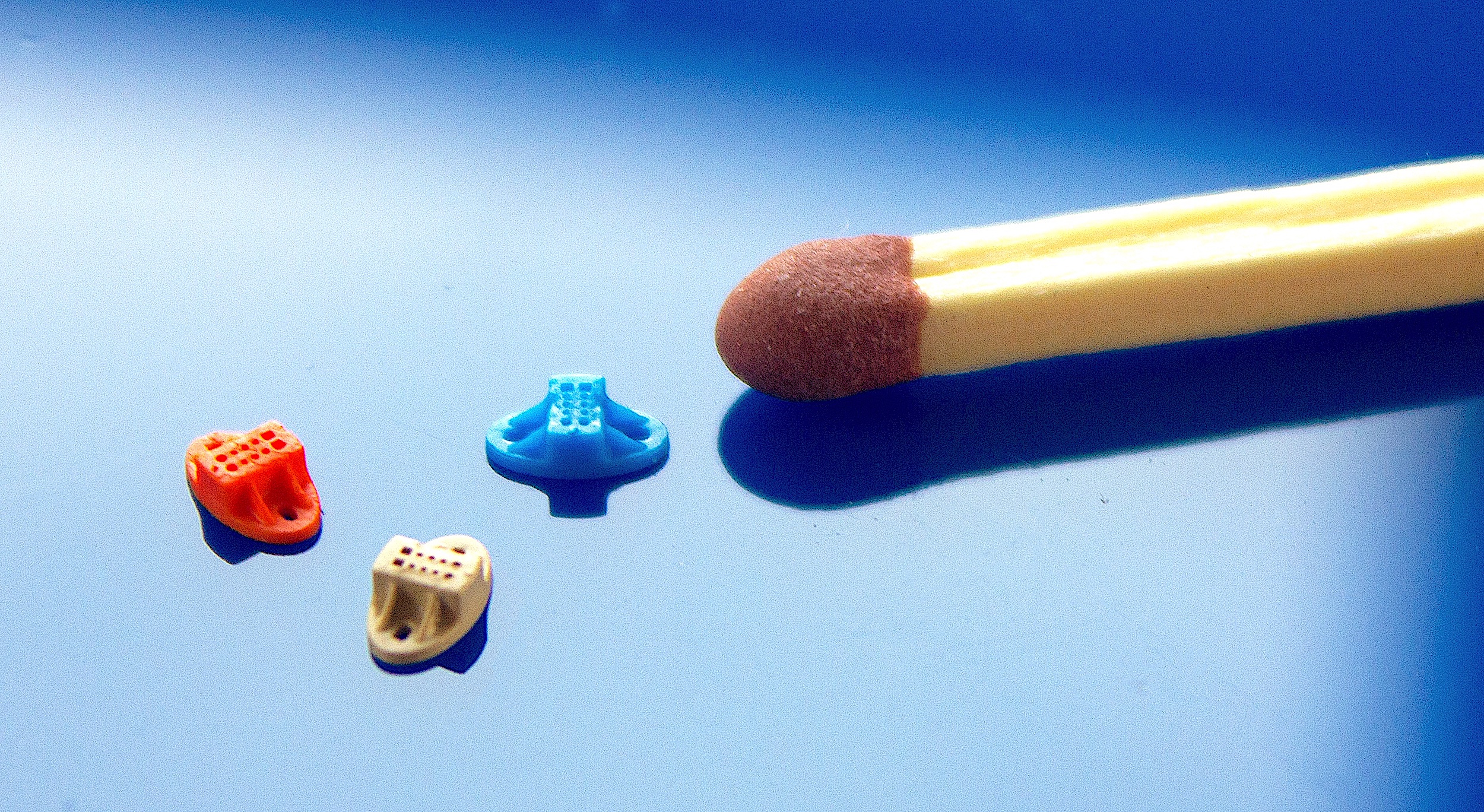

Photo: Advanced Micro molding technology in cleanrooms at Micro Systems for medical device manufacture

In addition, creating micro molds used for the micro molding process of microneedles also require a high level of expertise and technology. For example, micromilling uses ultrahigh speed, high accuracy, spinning single-crystal diamond cutting tools, to create master moulds for microneel micro molding process.

Microneedle manufacture at Micro Systems

Micro Systems has more than 20 years of experience in designing and manufacturing ultra-precision molds, as well as injection molding, for advanced medical devices. We can support you from the very first step of the project, throughout to the final mass production of microneedles. Our in-house mould manufacture and molding teams allow us to provide you with comprehensive turn-key manufacturing solutions that will unlock your microneedle manufacturing potential.

Contact us today to discuss your microneedle project!

Packianather MS, Le CH, Pham DT et al. Advanced micro and nano manufacturing technologies used in medical domain. InIFMBE Proceedings 2016; 2016: 120–123.