Mold making perfection: Micro Systems’ continuous machining investment

Micro Systems, the UK’s leading precision medical mold maker, has invested up to £1M in new machinery in 2023, as part of the strategic ‘pattern of continuous investment’.

To support the growing demand from the global markets as well as to further boost production efficiency, reduce lead times and costs, the Haydock-based company has invested £1M in 2023 on new machines, including a Werth CT Scanner, a Custom Agie X400 Milling machine and an Agie Wire Cut 2000 X machine.

Photo: The latest machinery additions in 2023 at Micro Systems

Along with other top-of-the-line equipment, the recently added Werth CT Scanner brings in-house the capability to quickly generate detailed 3D scans of steel mold inserts or moulded plastic components which can be cross-checked against 3D models with GOM CAD Comparison software to highlight any adjustments which need to be made. This ultimately leads to quicker development iterations to shorten lead times during testing and validation.

The 2 new Agie machines increase Micro Systems’ capacity by improving production efficiency and automizing production processes, to reduce delivery time across a larger number of projects, ultimately benefiting our customers. Importantly, the machines also support Micro Systems with their responsible machining journey through the focus on design and energy efficiency, with the machines boasting a more efficient exhaust system and intelligent temperature control.

With these latest additions, along with more than 20 years of experience, Micro Systems has increased capacity, reduced lead times, and enabled more efficient mould development and validation phases. In addition, the increased machine efficiency achieved from this investment can benefit customers with more competitive mold prices.

Talking about this investment, Alex Clark, Sales and Marketing, said: “Our investment this year shows our continuous commitment to further increase our manufacturing capabilities, especially with an increasing number of challenging requests from customers from all over the world. For the coming 2024 year, we will continue looking into further investment opportunities that strengthen our position as a leading mold maker in not only the UK but also on the global markets”.

Looking forward, Micro Systems expects to continue with the commitment to improving technology and capabilities through investment on machinery and training, securing its position as one of the leading precision mold makers, driving the industry with innovative solutions in ultra-precision molds, molding and micro injection molding using groundbreaking engineering techniques.

About Micro Systems

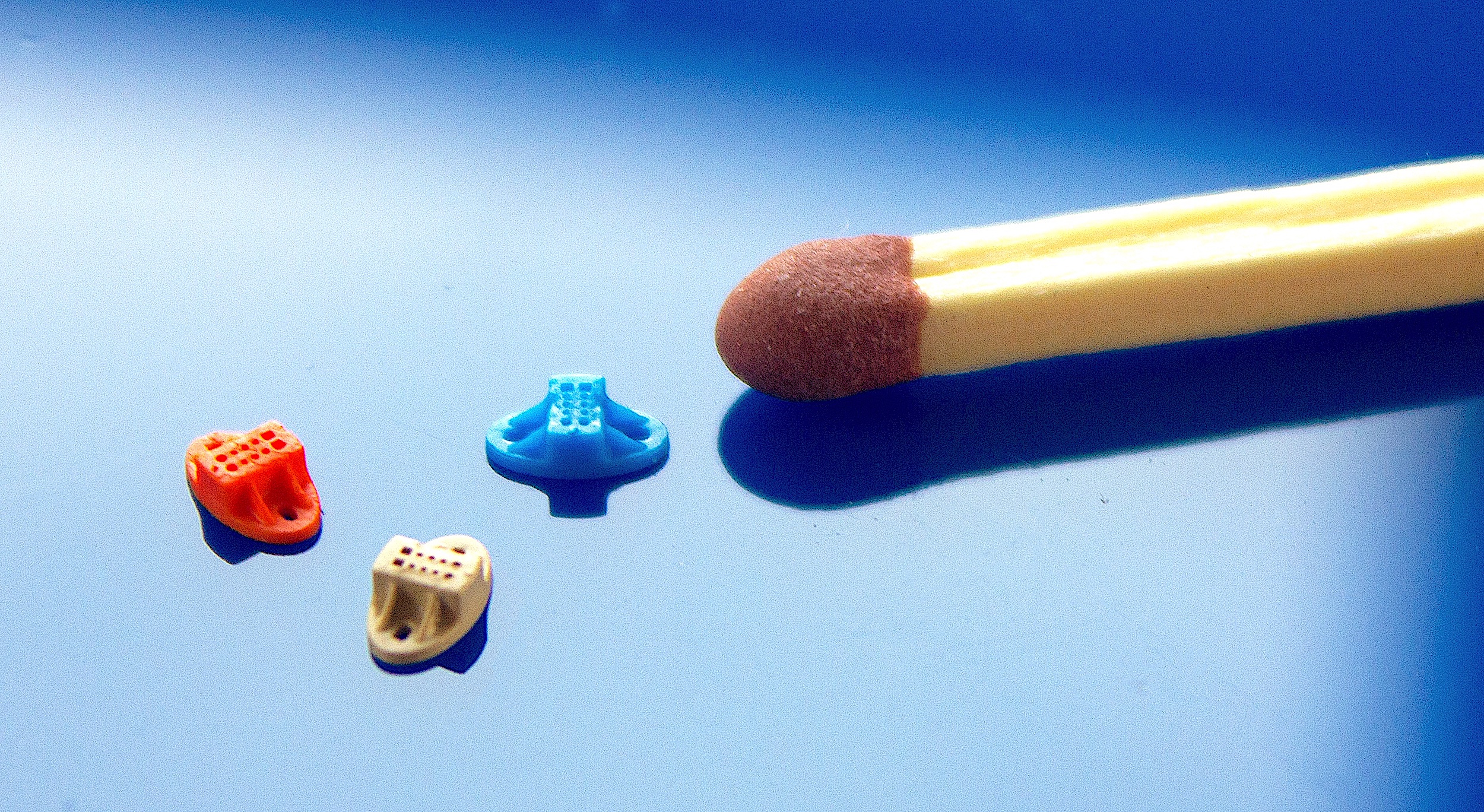

Micro Systems is a leading manufacturer in precision-engineered injection molds and micro molds for the medical, pharmaceutical and ophthalmic markets. Micro Systems offers innovative solutions for designing and manufacturing multi-cavity, high-volume molds, and turnkey solutions for medical device manufacturing needs, with Class-7 cleanroom production capabilities. In addition to mold making and component supply, Micro Systems also provides factory acceptance testing (FAT), mold validations and technical moulding support as part of our comprehensive service. The company is ISO 9001 and ISO 13485 certified, and has facilities in Warrington, UK and in Singapore

Micro Systems (UK) Ltd

101 Golborne Enterprise Park, Warrington, WA3 3GR