Injection Molding

THE ULTIMATE INJECTION MOLDING PARTNER

Micro Systems delivers ultra-precise plastic injection molding, with sub-micron accuracy and surface finishes under 10 nm. Recognized as one of Europe’s most advanced medical molding facilities, we process high-performance polymers like PEEK, COC, COP, PMMA, and PBT, from prototype to mass production.

- 2-shot Molding

- Micro Molding

- Over Molding

- Insert Molding

- Implantable/Bioabsorbable Material Molding

MEDICAL MICRO INJECTION MOLDING SOLUTIONS

Micro Systems specializes in micro-molded components for medical and pharma applications. Each production cell features robotic handling and in-line vision systems for real-time quality control and tray packaging, ensuring component integrity at every step.

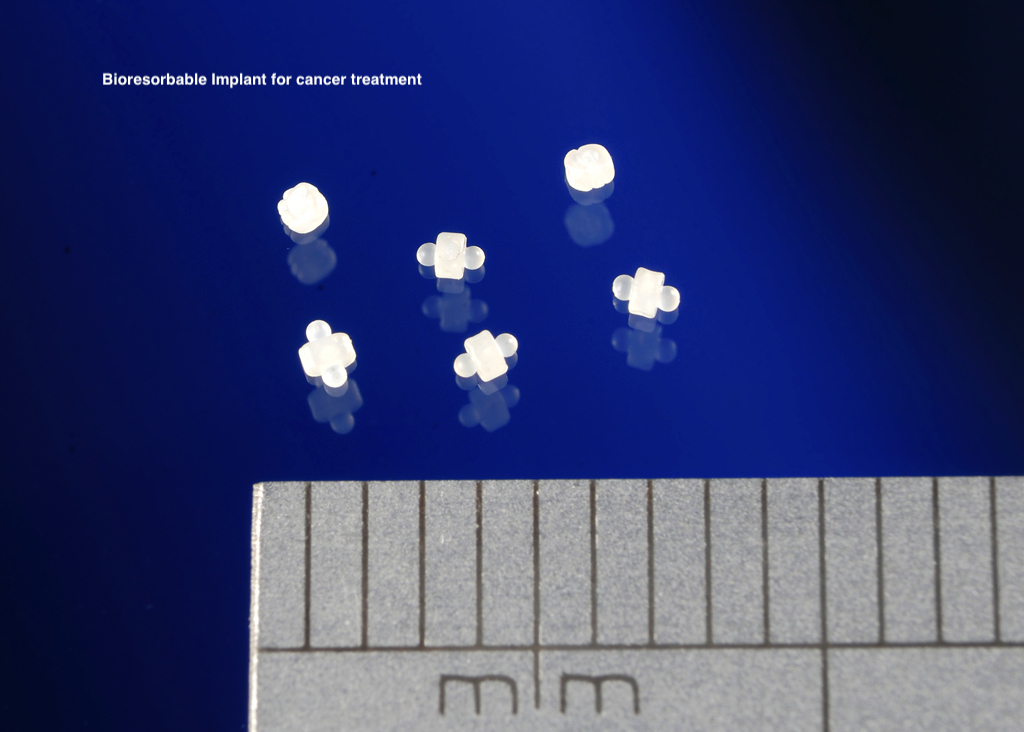

- Bioabsorbable implant for cancer treatment

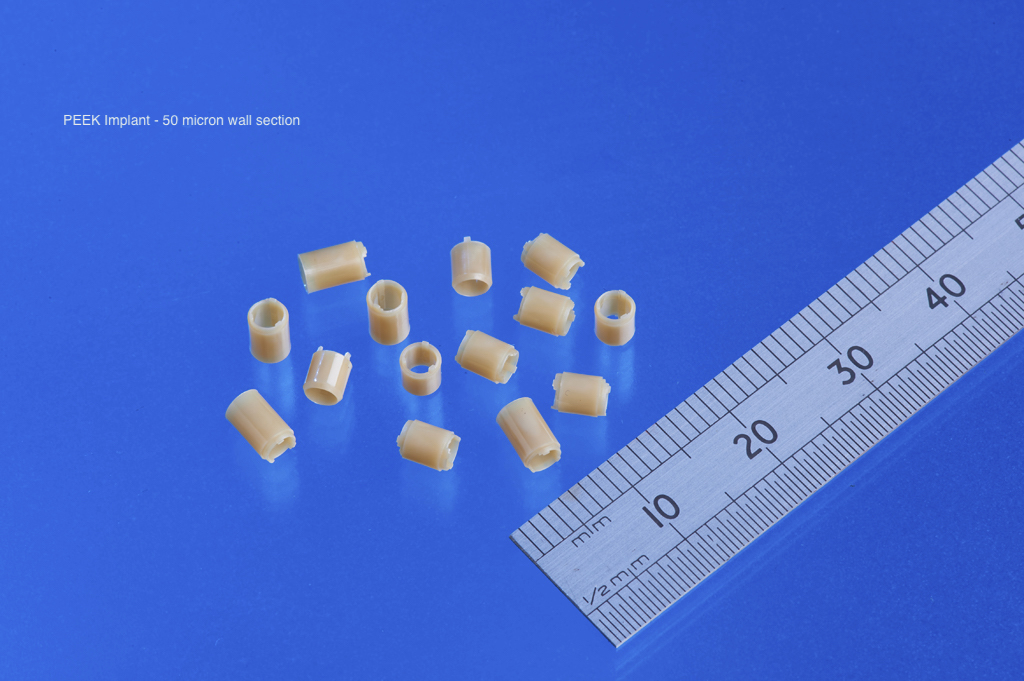

- PEEK implant

- Soft mist inhaler

- Injector pen

- Drug delivery system

- Microfluidics diagnostic system

ADVANCED INJECTION MOLDING TECHNIQUES

We deliver high-precision, multi-material over-molding with guaranteed shot-to-shot consistency—eliminating contamination and costly assembly. Capabilities include 2-shot, 2K, and thin-wall molding for complex, high-performance components.

With decades of in-house expertise, we solve complex molding challenges using advanced techniques, delivering high-performance injection molded parts that bring your designs to life.

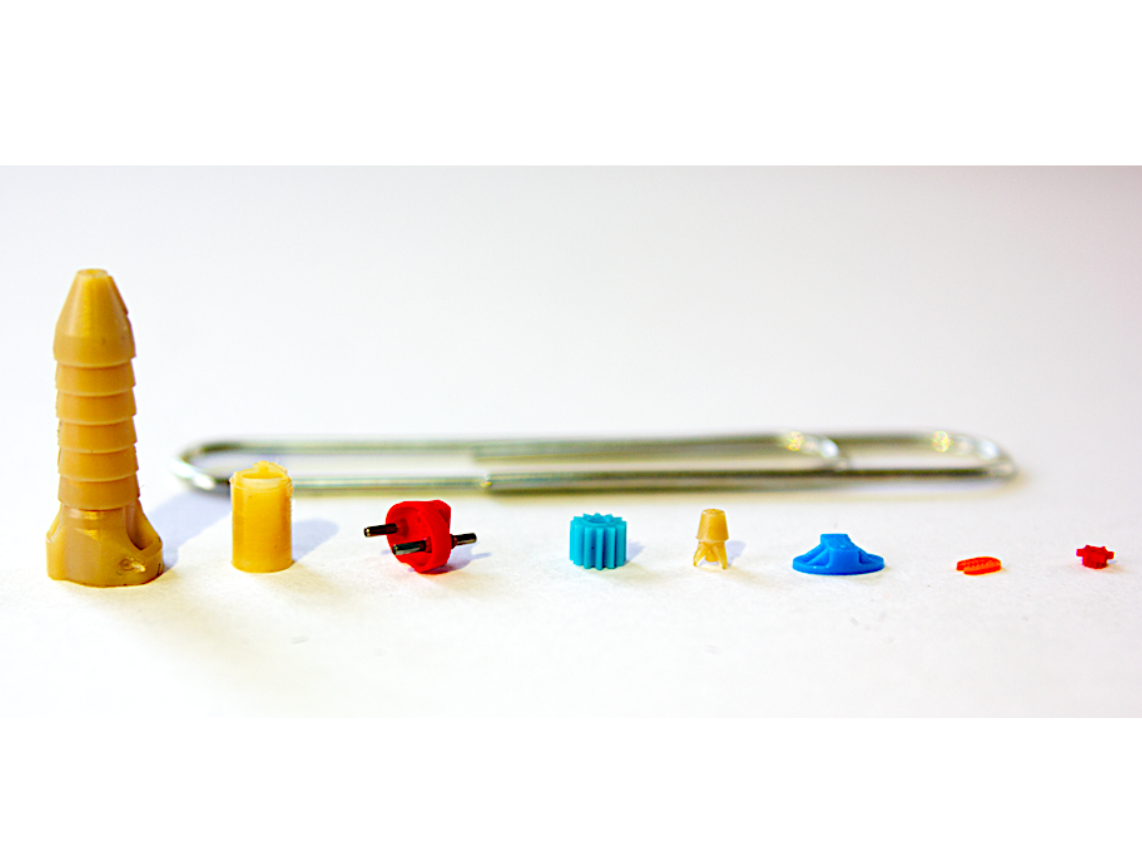

INJECTION MOLDING EXAMPLES

Bioresorbable Implant.

Cancer Treatment

Micro Nozzle.

0.05 Orifice

PEEK Implant.

50 micron wall section

Microfluidic chip.

25 nm surface finish with integrated optic features.

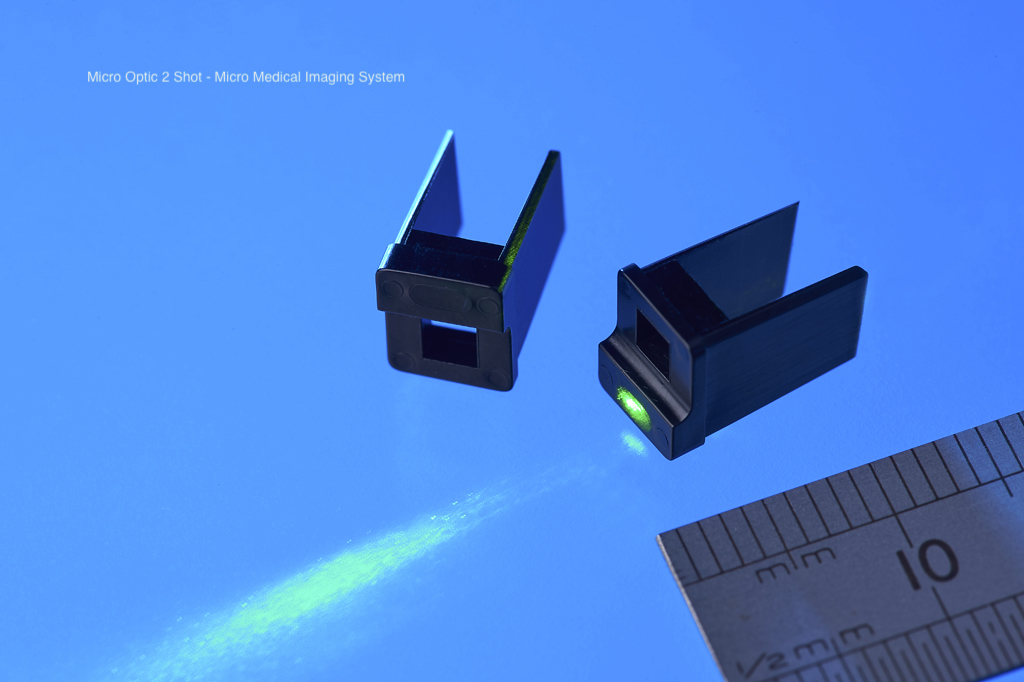

Micro Optic 2 Shot.

Micro Medical Imaging System

PEEK Bone Implant.

Replacing Titanium