Technologies

THE LATEST SOFTWARES

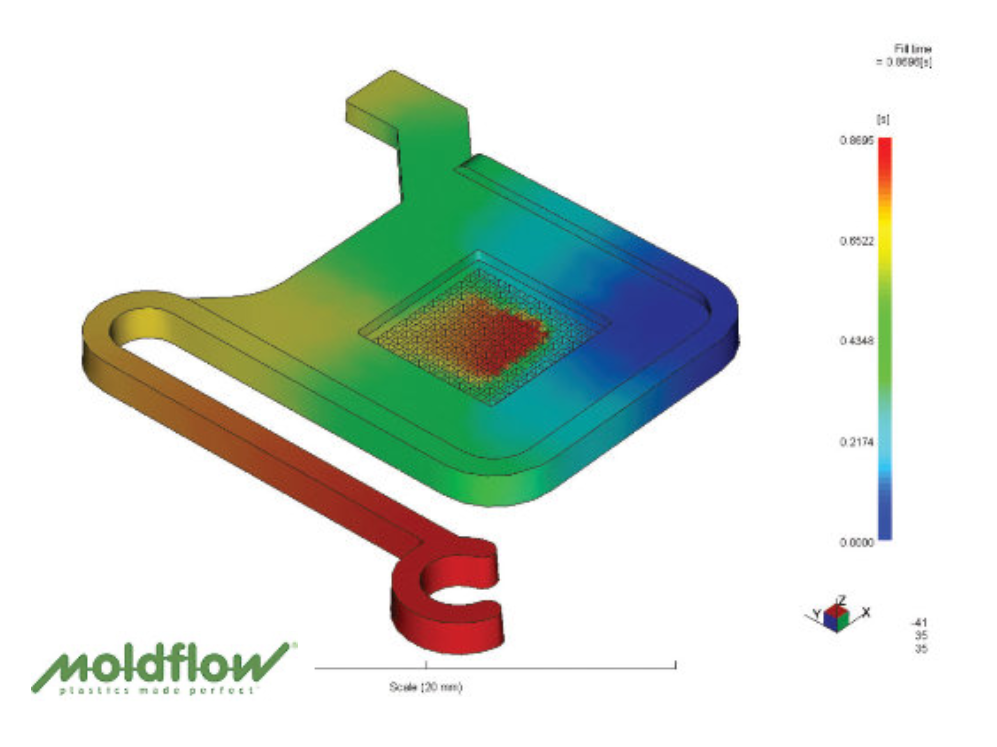

We design in Siemens NX and 3D Moldflow, with continuous training to push design boundaries. Tech-enabled project management ensures on-time delivery and precision – every time.

CONTINUOUS INVESTMENT IN MODERN MACHINERY

We invest over £500k annually in advanced machinery for mold making and injection molding, equipping our facility with some of the most sophisticated systems in the industry.

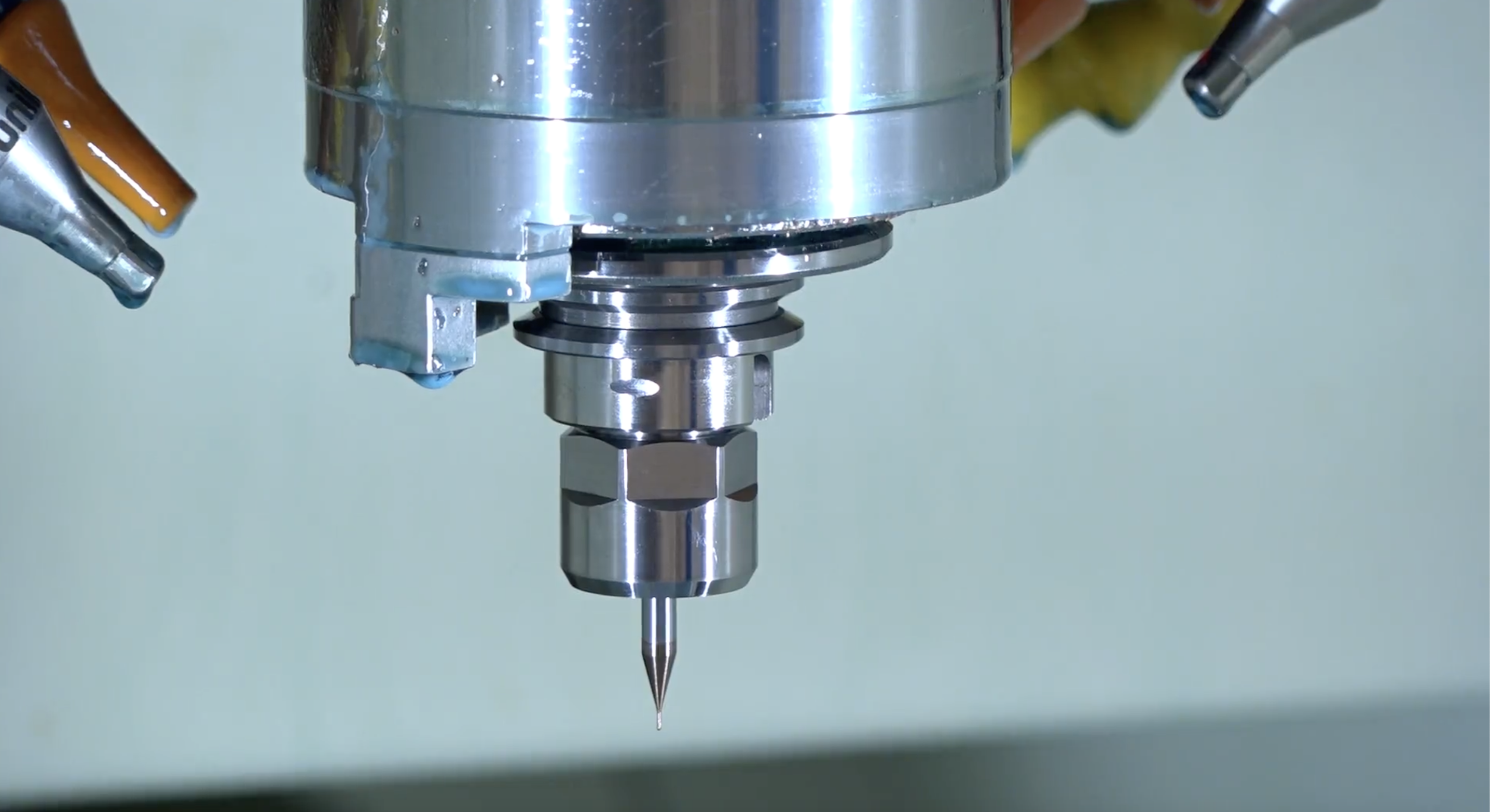

WEDM machine: cut through hardened steel with a wire diameter of 30 microns (0.0013”), positional accuracy of 0.001mm (0.00004”)

5-Axis Micro Kern Milling: cut through hardened steel with a cutter diameter of 50 microns (0.002”), positional accuracy of 0.0005 mm (0.00002”).

Wittmann-Battenfeld Micropower micro molding machine: effective molding process for the smallest parts possible.

QUALITY CONTROL IN MANUFACTURING

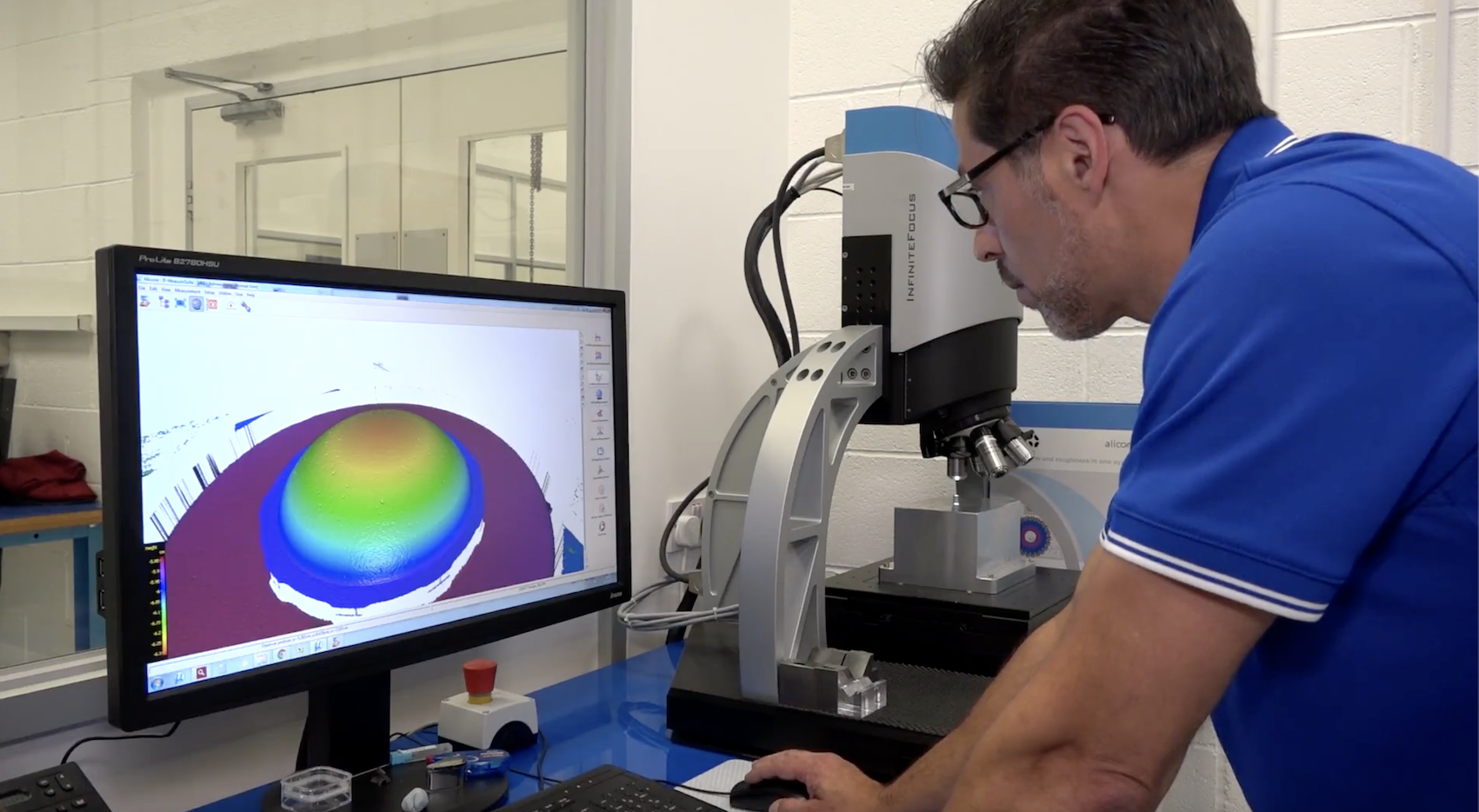

With continuous investment in cutting-edge micro metrology, we reduce lead times, accelerate design updates, and lower costs. Our top metrology machines include:

Several CMM Vision and Probe Systems: deliver tolerances of 1μm.

GOM Software for 3D Measurement Data: used for shape and dimension analysis, 3D inspection and mesh processing for 3D point cloud and CAD data sets.

Digital Microscopes: scan 3D data with a maximum resolution of 10 nanometres.

Interferometer: scan 3D data with a maximum resolution of 0.2 manometer.

CTScan Computed Tomography: measure, analyze, inspect hidden defects and inner structures