The Role of Micro Molding in Lens Making

In the world of precision optics, the manufacturing of lenses involves highly sophisticated techniques, where even the smallest deviation can affect the performance of the final product. With technological advancements, micro molding has emerged as an indispensable method in lens production, revolutionizing the industry and enabling the creation of increasingly complex and miniature lenses.

What is Micro Molding?

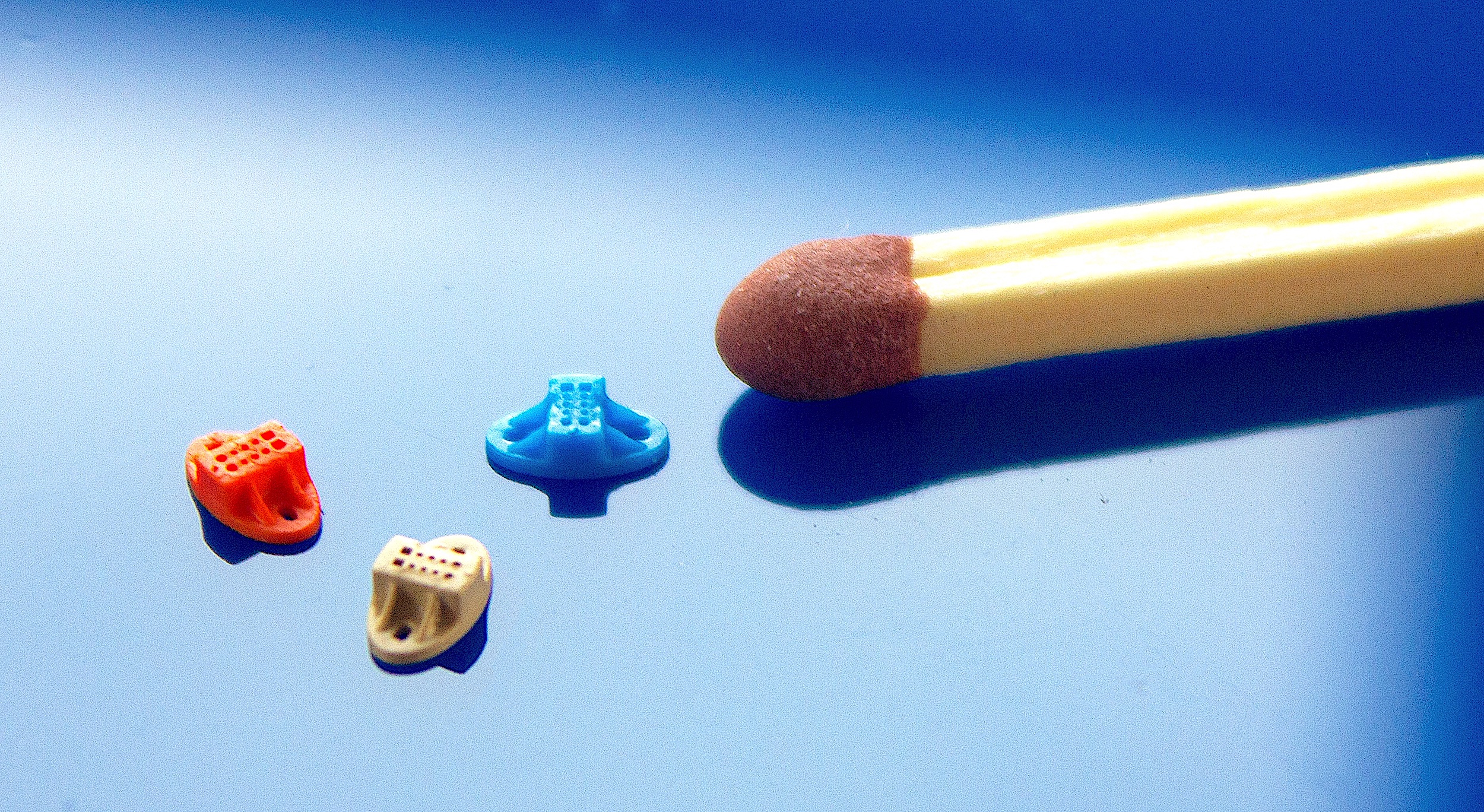

Micro molding, is a manufacturing process where miniature parts are produced by injecting molten plastic or other materials into precision-engineered moulds. The moulds are typically made with extremely fine details, allowing for the creation of very small, high-precision components. Micro injection molding can produce parts as small as a few millimeters in size and features down to 10 microns in diameter. The key advantage of micro molding lies in its ability to produce parts with extremely tight tolerances, which is essential in lens making, where even micrometer-level precision can be crucial to the optical performance of a lens.

Photo: Micro injection molding helps achieving manufacturing tiny items of extreme precision and detail (Micro Systems)

Advantages of Micro Molding in Lens Making

High Precision and Detail

Micro molding can achieve incredibly high levels of precision, with tolerance ranges down to the micrometer scale. For lens manufacturing, where the curvature and surface smoothness are essential to the optical properties, the precision offered by micro molding allows for the creation of lenses with consistent optical quality across mass production. This precision ensures that each lens, no matter how small, performs as expected.

Furthermore, as lens size can go down to the micro level, precision in achieving tiny detail is crucial. For example, micro lenses for applications like endoscopy, microscopes, camera sensors, and smartphones, can be as small as less than 1 mm in diameter, in some cases, the diameter can go down to 200 microns (0.2 mm) or even 100 microns (0.1 mm). Miniature lenses, like those found in contact lenses or small optical devices, can range from 1 mm to 10 mm in diameter, with some of the more complex designs reaching as small as 2 mm or 3 mm in diameter.

Cost-Effectiveness for Mass Production

One of the most significant advantages of micro molding is its cost-effectiveness when producing large volumes of parts. Traditional methods such as grinding and polishing can be time-consuming and labour-intensive, particularly when scaling up production. Micro moulding technology, on the other hand, is highly automated and can produce thousands of parts in a short amount of time, reducing production costs significantly. This makes it an ideal choice for industries that require mass production of lenses, such as the consumer electronics and automotive sectors.

Complex Geometries and Miniaturisation

The micro molding process allows for the creation of lenses with intricate geometries that would be difficult or impossible to achieve through traditional methods. This is particularly important in the production of miniature lenses used in devices like cameras, smartphones, and medical instruments, where space is limited and complexity is required. Micro molding enables the production of ultra-small lenses with complex shapes, including lenses that require multiple surfaces or integrated features, such as micro-optical systems or multi-focal lenses.

Material Versatility

Micro molding is compatible with a wide range of materials, including plastics, elastomers, and even some metals. For lens making, this is particularly important because different materials can be chosen based on their optical properties. High-performance optical materials such as optical-grade polymers can create lenses that are not only lightweight and durable but also optically clear. Additionally, micro molding can support the production of lenses that incorporate coatings or other treatments during the moulding process, improving both their performance and longevity.

Reduced Waste and Efficiency

Compared to traditional lens manufacturing methods, micro molding generates significantly less material waste. Since the moulding process is highly controlled and precise, manufacturers can achieve high yields with minimal scrap material. This contributes to both environmental sustainability and cost savings for manufacturers, making micro molding a more efficient and eco-friendly alternative to older techniques.

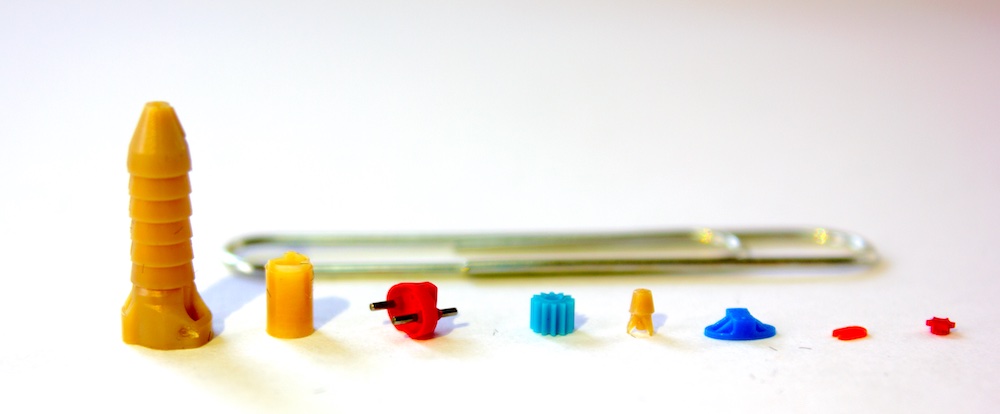

Photo: Well-designed micro mold allows micro injection molding to be precise and efficient

Applications of Micro Molding in Lens Making

Micro molding has found wide applications in several industries that rely on high-performance lenses:

Consumer Electronics

In the world of smartphones, cameras, and wearables, lenses are an essential component. Micro molding allows manufacturers to create small, high-precision lenses that fit into compact spaces while maintaining excellent optical performance. The demand for miniaturization and the increasing functionality of mobile devices make micro molding indispensable in the lens-making process.

Medical Devices

Medical imaging devices, such as endoscopes and microscopes, require lenses that offer high optical clarity in small, compact sizes. Micro molding helps to produce lenses for these devices with consistent quality, allowing for better diagnostics and imaging performance. Additionally, lenses for surgical tools and diagnostic instruments can be manufactured with precision to meet the stringent requirements of the medical field.

Automotive Industry

In modern automotive applications, optical lenses are common in various systems, including cameras, sensors, and light sources. As the automotive industry continues to integrate advanced technologies like autonomous driving and advanced driver-assistance systems (ADAS), the need for small, high-performance lenses has grown. Micro molding provides an efficient way to produce these lenses at scale, ensuring optimal functionality in demanding environments.

Photo: High-tech micro injection molding machines in ISO Class 7 Clean room at Micro Systems

Micro molding has become an essential technique in the lens-making industry, offering precision, cost-efficiency, and the ability to produce miniature lenses with complex geometries. Its role in industries such as consumer electronics, medical devices, automotive, and aerospace is growing rapidly, as the demand for smaller, more powerful lenses increases. With more than 20 years of experience in mould design and manufacture, and micro injection molding, Micro Systems can meet your expectation in delivering a turn-key micro-optic lens project. Contact us today!