What is two-shot injection molding?

Two-shot molding, also known as multi-shot, double-shot, and dual-shot molding, is an injection molding procedure where two different plastic resins are molded together within a single machining cycle. These substances are administered sequentially rather than simultaneously, and the product is not discharged from the mold in between the two shoots, but it is produced in a single step.

What is the two-shot injection molding process?

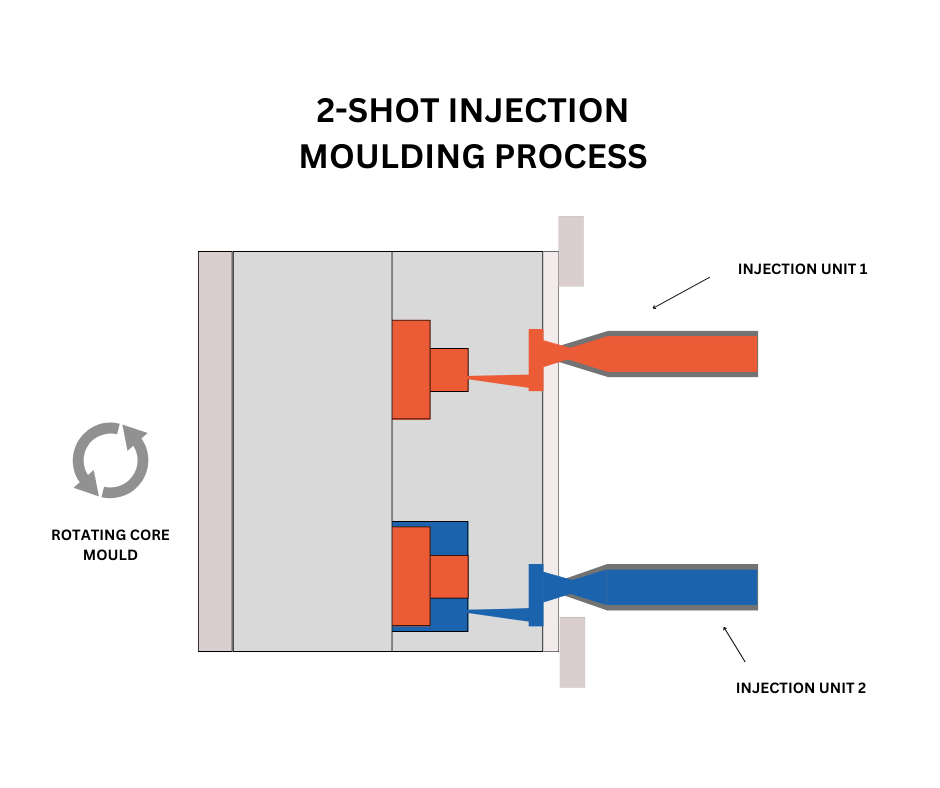

Since the procedure is completed in a single step, just one mold tool is needed for two-shot molding.

The first shape of the product is created when the first polymer (the substrate) is injected into the chamber of the first-shot tool. After rotating 180 degrees and separating while still holding the first shot, the mold tool closes with the first shot aligned with the second cavity of the tool. Over the substrate, the second polymer is injected into the second-shot cavity. The finished molding is then pushed off the mold tool once the tool has been turned 180 degrees back to where it started.

What are two-shot injection molding applications?

For complex, multi-colored, and multi-material plastic goods, especially in high-volume manufacturing circumstances, two-shot injection molding is the best plastic molding technique. Two-shot molded parts are utilized in almost every industry, from consumer products to construction, such as toys, automobile components, medical equipment, containers, and toiletries. Two-shot molding is common in the production of:

- Toys

- Containers

- Toiletries

- Gardening tools

- Movable parts

- Surgery and medical equipment

- Kitchen utensils

- Other multi-colour, multi-material parts

What are the benefits of two-shot injection molding?

As two-shot injection molding does not require several production phases, it offers molding manufacturers a number of benefits, including reduced manufacturing costs, improved ergonomics and aesthetics, superior mechanical bonding, quicker production times and more efficient material usage. Engineers can readily produce multi-material and multi-colored items as a consequence, without the need for additional machining stages.

Reduced manufacturing costs:

As the number of parts in a final assembly is decreased with two-shot injection molding, there could be a huge saving in research and development, engineering, and validation expenses for each increased part number.

Improved aesthetics and ergonomics:

Products created using a two-shot method can maintain the necessary structural characteristics while being aesthetic and ergonomic appealing. The load-bearing structural component can be molded in the first phase of this procedure, and the finishing touches can be applied in the second step using a more attractive material. It is also simple to cover or add to structural plastic with materials that are more suitable for human contact as it offers a greater grip and a gentler touch, soft, rubbery material is more suited for human hands.

Superior mechanical bonding:

Given excellent material selection, the product’s various levels join together molecularly throughout the molding process, hence, the bond is frequently more durable than traditional molding and assembly and even more durable than other cutting-edge techniques like over- and insert molding.

Quicker production time:

As there is frequently no need to do secondary assembly of the item since many tiers of a product can be added during this operation, injection molders could significantly reduce production time. While the time of one cycle could be longer compared to the traditional injection molding process, it is still faster than running 2 separate cycles to make the same item.

More efficient material usage:

Two-shot molding could help combine the greatest qualities of different materials, to create complex mold patterns with strong bonding to ensure durability and longevity.

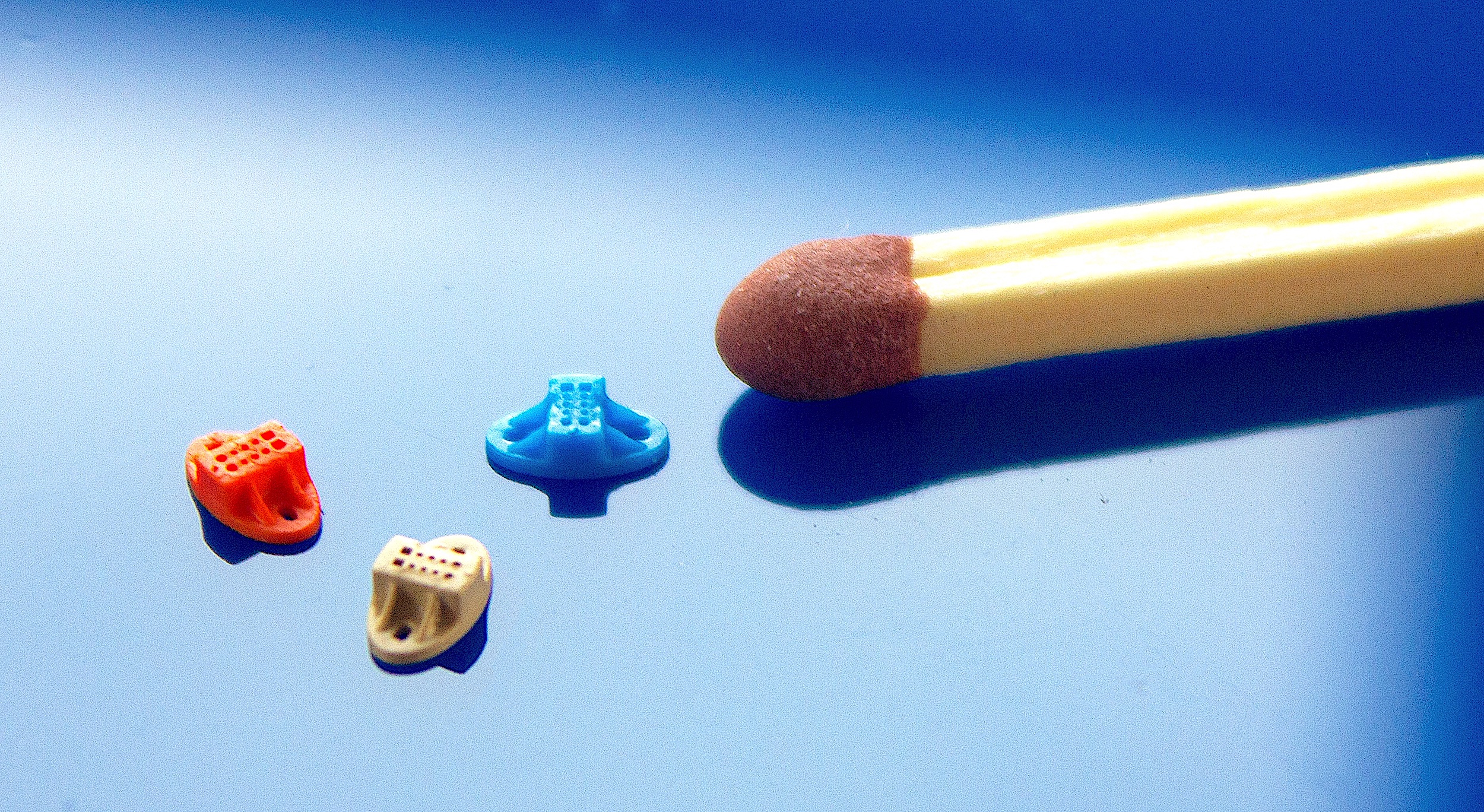

(Photo: Micro Systems)

Micro Systems is a UK based manufacturer of medical molds, micro molds and medical injection-molded parts. We cater for our customers starting from mold design through mold manufacturing and development to validation within an ISO Class 7 cleanroom. We are ISO 13485 and ISO 9001 certified. Contact us today to get the best quote for your medical injection molding project.